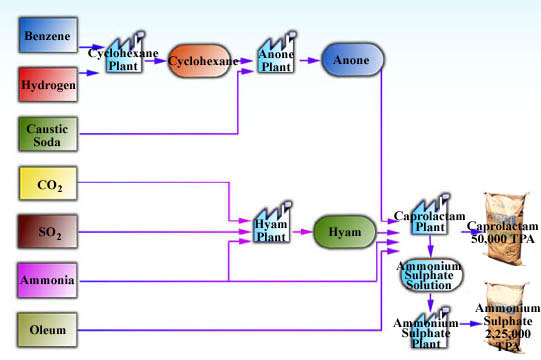

FACT-Petrochemical Plants of Fertilisers and Chemicals Travancore Limited (FACT), Udyogamandal Complex , Kochi is in the business of manufacture and marketing of quality Caprolactam with production capacity of 50,000 MT of Caprolactam per annum. Caprolactam is a monomer of Nylon-6 which is a base material for a number of industrial products. Caprolactam is used primarily in the production of nylon 6 fibers and nylon 6 engineering resins and films. More than half of world caprolactam consumption is for nylon 6 fibers and more than one-fourth is for nylon 6 resins and films; the remainder is accounted for by trade in polymer chip. Nylon 6 fibers are used in the textile, carpet, and industrial yarn industries. Nylon resins are used as engineering plastics, with applications in the automotive industry, specialty film packaging for food, and wire and cabling. The process employed for the Caprolactam manufacture by FACT is the Raschig Route.

The license and process know-how was supplied by M/s. Stamicarbon b.v, a subsidiary of Dutch State Mines (DSM), The Netherlands. The basic engineering was done by M/s. Chiyoda Corporation, Japan and the detailed engineering was done by FEDO (FACT Engineering & Design Organisation) , the design and engineering unit of FACT. Along with the 50,000 MT of Caprolactam produced per annum by product of ammonium sulphate of 225000 MT per annum is also produced.

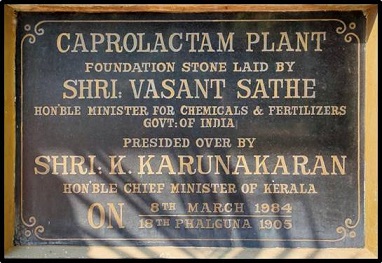

The foundation stone of the project [earlier known as the Ammonium Sulphate Caprolactam project

(ASCL project)] was laid on 8th March 1984. |

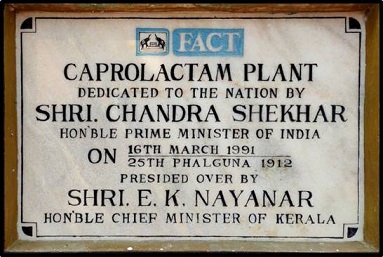

The plant was commissioned on 25th October 1990. The plant was dedicated to the nation by Hon Prime Minister of India Shri Chandra Shekhar on 16th March 1991. |

|

|---|---|---|

A brief description of the Caprolactam Manufacturing process is given below :-

Process Description

FACT-Petrochemical Plants comprises of following main sections :-

i) Anone Plant Benzene hydrogenation Cyclohexane oxidation

ii) HYAM (Hydroxylamine sulphate) Plant

iii) Lactam Plant

Besides this Effluent Treatment Section with Aerobic and Anaerobic treatment & Offsites area with ancillary facilities are also available.

|

|---|

The operations of the above sections are briefly described below.

Anone Plant

Hydroxylamine sulphate (HAYAM) Plant

|

|---|

The Pollution Control Facilities consist of Soda Ash Recovery Plant, Ammonium Sulphate Purge Incineration Plant, Effluent Treatment Section with Aerobic and Anaerobic treatment.

Ancillary facilities consist of :-

1) Steam Generation & Captive Power Plant of 16 MW.

2) Water Demineralisation Plant.

3) Cooling water treatment Plant.

4) Nitrogen Plant & Compressor house.

5) Main Tank Farm.

6) Ammonia Storage & Handling system.